Found this helpful? Share it with peers.

Introduction

Processes often look reliable on paper, yet their real performance can tell a very different story. Hidden delays, compliance issues, or wasted effort only come to light when execution is measured instead of assumed. Without that insight, organizations risk building decisions on blind spots.

Process Performance Management closes this gap by turning raw execution data into guidance for both daily work and long-term, strategic direction. It shows where performance meets expectations, where it falls short, and how those outcomes connect to business goals.

In this blog, we explain how Process Performance Management works, why it matters for both operations and strategy, what challenges to expect, and how to approach it successfully.

What is Process Performance Management?

Process Performance Management is a data-driven method for measuring and improving how business processes perform in reality. It uses key performance indicators (KPIs) to track efficiency, quality, and compliance, turning execution data into insights that guide continuous improvement and strategic decisions.

Why Process Performance Management Matters?

Process Performance Management matters because it connects process execution with real business outcomes. Without measuring performance, inefficiencies and compliance risks often remain hidden.

When done right, it helps organizations:

-

Improve efficiency by reducing rework, delays, and manual effort.

-

Ensure compliance through transparent, traceable performance data.

-

Support strategic decisions with facts, not assumptions.

-

Boost customer satisfaction by eliminating process bottlenecks.

-

Drive continuous improvement across teams and departments.

In short, you can’t improve what you can’t measure — and Process Performance Management makes that measurement possible.

Hint: Discover how to overcome performance issues and increase process efficiency.

How to Build a Process Performance Management Model

1. Define the Foundation and Goals

A performance initiative has to start with context. Define what success means in practical terms and agree on the outcomes that reflect strong performance in your key processes. Express these outcomes in ways that can be measured, and assign responsibility to those who influence the results.

Each initiative must remain anchored in business strategy. Review current priorities and long-term goals, then connect the relevant processes to them. This ensures that performance data is used to support real decisions, not collected in isolation.

2. Discover and Map Key Processes

Identify the processes most critical for performance tracking. Start with the ones that directly support strategic goals. Methods like impact analysis can help with that assessment by showing where changes would make the biggest difference. This lets you focus attention where it counts, since not every process has the same impact.

Once selected, map these processes to understand their main activities, responsibilities and outcomes. Don’t forget to consider process variants, exceptions, and real-world complexity – your performance insights are only as good as your process understanding.

3. Define KPIs and Assign Ownership

Once the key processes are selected and mapped, define the metrics that will reflect how they perform. Make sure the Key Performance Indicators (KPIs) you select are:

- Measurable: must be based on quantifiable data so that progress can be objectively tracked

- Actionable: must point clearly to actions that can improve performance

- Balanced: must include both forward-looking (leading) and results-based (lagging) indicators

Assign ownership for each process. Make it clear who monitors the data, who investigates deviations, and who takes action when performance slips. Performance management requires governance as much as it requires measurement.

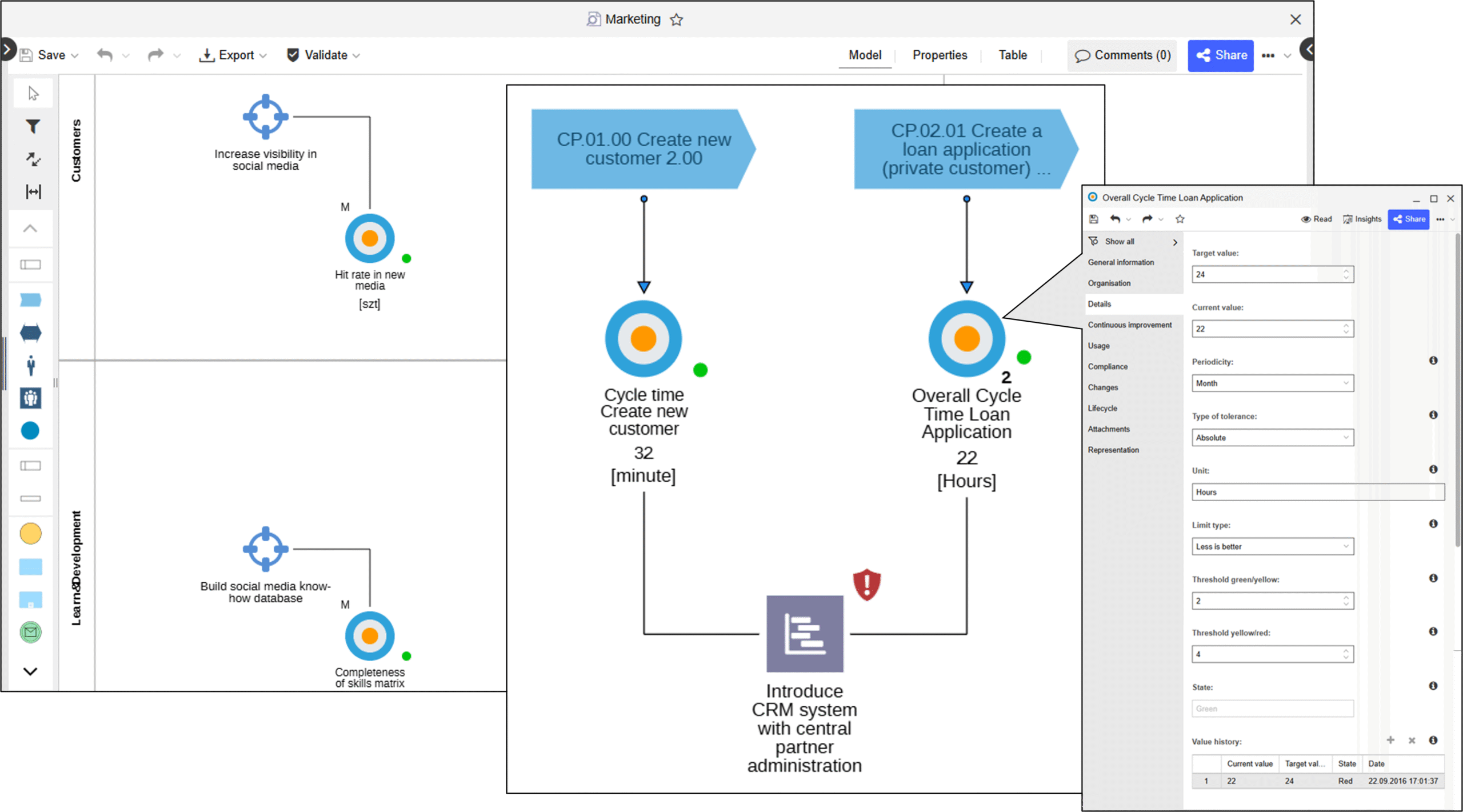

Embedding KPIs during process design in ADONIS

4. Collect Reliable Data and Build the Infrastructure

The next step is to define how data will be collected. Some of it may come from IT systems or be entered manually through user input. In other cases, automation tools may supply the data directly. Whatever the source, it must be consistent and reliable.

In parallel, prepare the infrastructure needed for ongoing, real-time monitoring. Once this is in place, connect your metrics to real process instances and set up the dashboards, views and alerts that will keep performance visible.

5. Monitor, Visualize, and Interpret

Make performance data accessible through dashboards or reports that are easy to navigate. Tailor the content to fit the needs of different audiences. Executives often require high-level summaries, while others may benefit from more detailed views with real-time alerts and visuals.

Presenting the data is only the starting point. To turn it into something useful, add context that makes interpretation easier. Benchmarks and comparisons help users understand whether a value reflects strong performance or points to an issue.

Hint: Discover the role of process monitoring in identifying bottlenecks and improving efficiency.

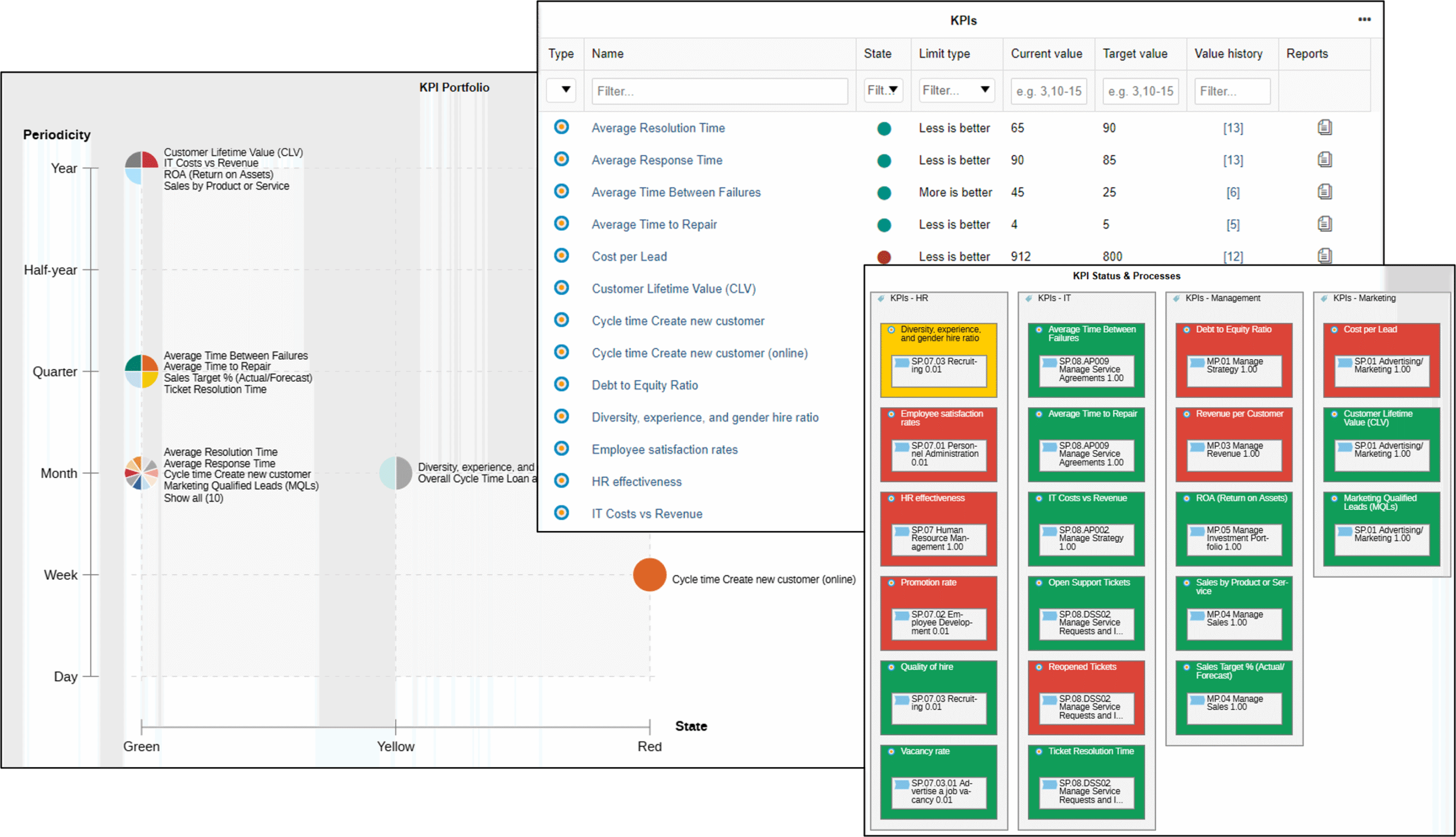

Turning performance data into insight with KPI dashboards in ADONIS

6. Continuously Improve and Adjust

Use insights to identify trends, bottlenecks, and improvement opportunities. Revisit your performance management setup regularly to ensure it continues to support strategic goals and decisions. Adjust metrics or processes as needed. These actions help keep your approach agile and responsive to changing business conditions.

How does Process Performance Management contribute to PMLC

A successful Process Performance Management strategy depends on the right tools — and that’s where ADONIS makes the difference. It transforms performance measurement from a manual effort into an integrated, automated practice.

With ADONIS, you can:

-

Embed KPIs directly in process models, ensuring that measurement is built into daily work, not tracked separately.

-

Visualize performance with customizable dashboards that highlight trends, deviations, and improvement opportunities.

-

Connect performance data to strategy, linking operational results with business goals.

-

Monitor processes in real time, using alerts to identify risks or delays before they impact performance.

-

Collaborate effectively, enabling teams to act on shared insights and continuously refine their processes.

By combining transparency, automation, and data-driven insight, ADONIS turns Process Performance Management into a continuous improvement engine — where processes aren’t just documented but actively managed for excellence.

How Does Process Performance Management Contribute to the PMLC?

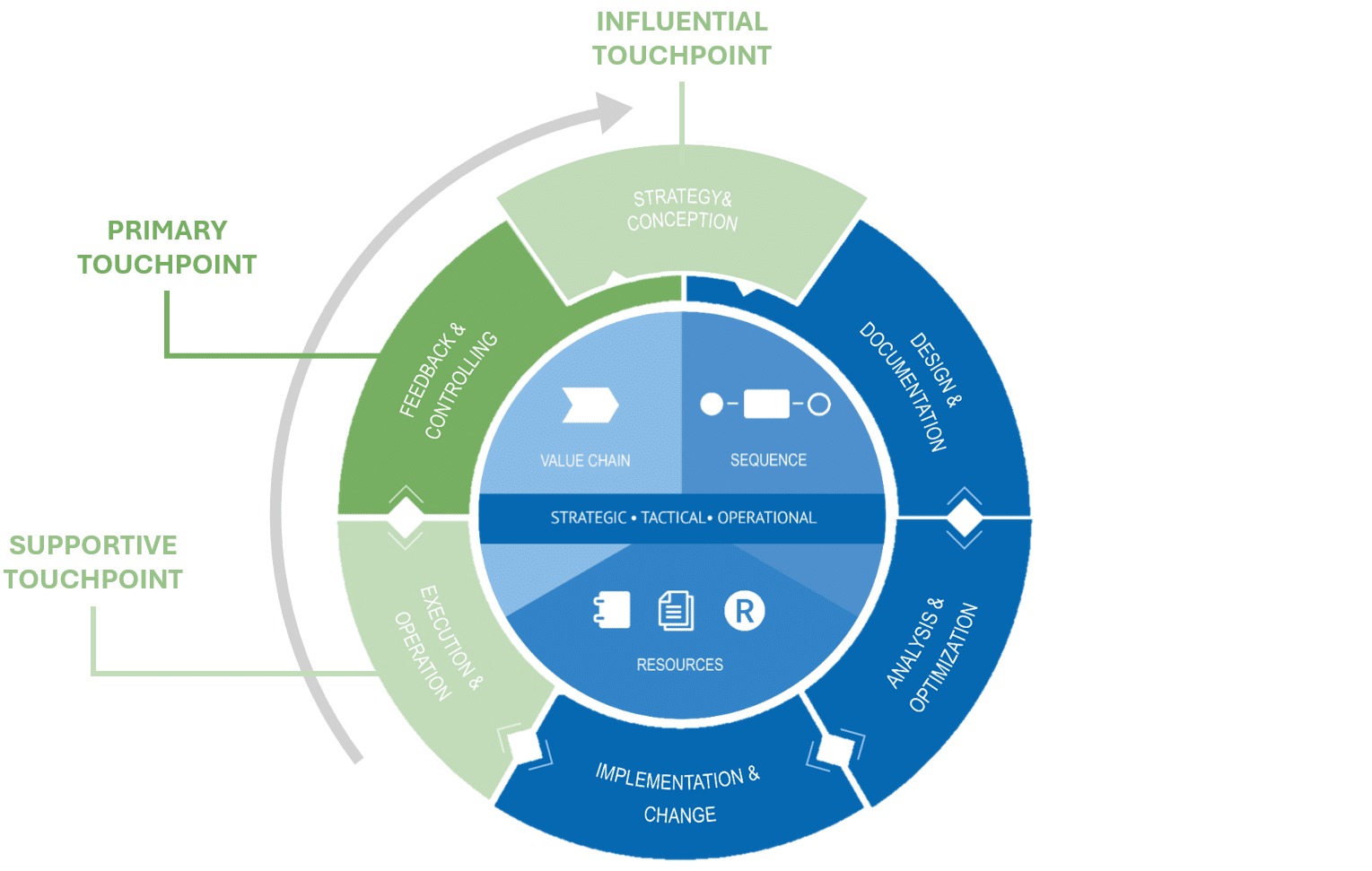

Process Performance Management plays a role at multiple stages of the Process Management Lifecycle (PMLC), with its core focus on monitoring, evaluation and improvement. It supports both strategic planning and day-to-day execution, linking high-level goals with operational performance.

Main touchpoints of Process Performance Management in the Process Management Lifecycle (PMLC)

Execution & Operation (Supportive Touchpoint)

This stage generates the operational data that feeds Process Performance Management.

Related activities that usually happen on this stage are:

- Generate and collect performance data

- Maintain dashboards for ongoing process monitoring

- Introduce warnings or alerts for deviations and violations

Feedback & Controlling (Primary Touchpoint)

This stage focuses on measuring process performance through KPIs and monitoring tools. It serves as the primary point of engagement for Process Performance Management within the lifecycle.

Related activities that usually happen on this stage are:

- Visualize performance data

- Comparing actual vs. target performance

- Identifying and validating improvement opportunities

- Feeding back into strategy or redesign

Strategy & Conception (Influential Touchpoint)

Process Performance Management provides strategic insight through performance indicators, and informs goal-setting, KPI definition, and resource allocation.

Related activities that usually happen on this stage are:

- Using past performance data to define clear and realistic goals, objectives and measurable KPIs

- Aligning business strategy with measurable process outcomes

Other Stages (Indirect Linkages)

Several additional stages in the Process Management Lifecycle also connect to Process Performance Management, though more indirectly:

- Design & Documentation – Incorporate the previously defined goals, objectives and KPIs during process design

- Analysis & Optimization – Use performance data to identify gaps and potential improvements

- Implementation & Change – Apply changes based on insights drawn from performance metrics

Enhancing Process Performance Management

To get the most out of Process Performance Management, strengthen it with targeted approaches and techniques that amplify its reach and effectiveness.

1. Turn Insights into Action with Process Automation

Process Automation can be a highly valuable investment for organizations looking to improve efficiency, reduce costs, and increase their operational productivity. By considering the right approach and carefully selecting the right targets for automation, organizations can ensure the success of their process automation initiatives.

Process Performance Management often highlights manual tasks that slow execution or cause variation in results. These issues can be resolved with automation, which applies rules consistently and reduces dependency on human effort. In the context of the Process Management Lifecycle, automation links analysis to action. It ensures that performance gaps do not just remain visible but are systematically addressed and closed.

2. Discover How Processes Really Run with Process Mining

Unlike traditional process analysis approaches that often rely on assumptions, Process Mining gives an objective view driven by real-life data. It helps identify hidden delays, rework or inefficiencies in executions, and it can connect performance drops with specific process behaviors so the organizations can better understand the root causes of the deviations. Beside this, it also enables continuous performance diagnostics over time.

Process mining also complements simulation and automation. While simulation explores how a process might perform under specific conditions, only execution data reveals what actually happens. Process mining provides that validation and helps identify where automation can replace manual, non-value-adding tasks.

Hint: Curious about how process simulation, mining, and automation work together? Explore our case study for a practical, step-by-step guide to combining these techniques effectively.

3. Align Effort with Impact Through Strategy Management

When supported by strategic thinking, Process Performance Management becomes more than an operational tool. It turns into a mechanism for long-term execution. By linking process-level metrics to business goals and focusing on improvements with high strategic value, performance management can support planning rather than just respond to problems. This shift helps organizations move beyond quick fixes and develop a habit of making progress toward larger objectives.

It is also much easier to get stakeholders on board when they see how process improvements help hit company targets. This becomes especially important when those targets shift. With a strategy-driven approach, performance management helps processes evolve in line with the organization’s direction.

Key Challenges of Process Performance Management

1. Technical and Infrastructural Challenges

Performance management relies on consistent, high-quality data, but many organizations struggle with fragmented systems and incompatible formats.

Common issues include:

-

Data scattered across multiple tools and legacy systems.

-

Inconsistent or incomplete records leading to unreliable insights.

-

Integration difficulties that prevent a unified performance view.

Solution: Establish data standards early, invest in integration capabilities, and ensure your BPM tools, like ADONIS, provide a single source of truth for all process information.

2. Organizational and Cultural Challenges

Performance initiatives often fail due to lack of resources or resistance to change. Employees might see monitoring as micromanagement, not improvement.

-

Limited time or budget to act on findings.

-

Resistance from teams comfortable with existing processes.

-

Lack of accountability or ownership of KPIs.

Solution: Build a culture of transparency and collaboration. Communicate that measurement enables improvement, not control, and tie performance goals to shared success.

3. Measurement and Decision-Making Challenges

Having data is one thing; knowing how to use it is another. Many teams struggle to interpret results or to translate them into action.

-

Skills gaps in analytics or KPI interpretation.

-

Overreacting to data without context or validation.

-

Automating decisions too quickly, without human oversight.

Solution: Combine data analysis with domain expertise. Empower process owners to interpret metrics critically and ensure that automation remains under guided human supervision.

In short:

Effective Process Performance Management isn’t just about tools — it’s about creating the right ecosystem of data, people, and decision-making to make continuous improvement sustainable.

Turning Data into Decisions

Process Performance Management turns process data into direction. It bridges the gap between how work is planned and how it actually happens, helping organizations identify inefficiencies, measure progress, and act with confidence.

When embedded into daily operations, performance management becomes more than a reporting tool — it becomes a mindset of continuous improvement and strategic alignment.

With ADONIS, you can take this approach further. By linking metrics, monitoring, and strategy within one platform, ADONIS helps you move from tracking performance to truly managing it, driving measurable impact across every process.

Start turning process data into decisions with ADONIS — your platform for performance-driven BPM.