Found this helpful? Share it with peers.

Introduction

Writing good Standard Operating Procedures (SOPs) play a crucial role in the Process Management Lifecycle, specifically in translating theoretical processes into actionable practices. As an integral part of the execution phase, SOPs bridge the gap between documented strategies and their practical application.

At its core, an SOP acts as a detailed instruction manual, guiding individuals through standardized steps to accomplish specific tasks. Think of it as a recipe book for tasks within an organization—providing clarity, consistency, and quality in execution.

If you are new to the topic, visit our blog to learn more about what Standard Operating Procedures are, or read on to find out how to create one effectively.

Standard operating procedure steps

1. Identify the Process

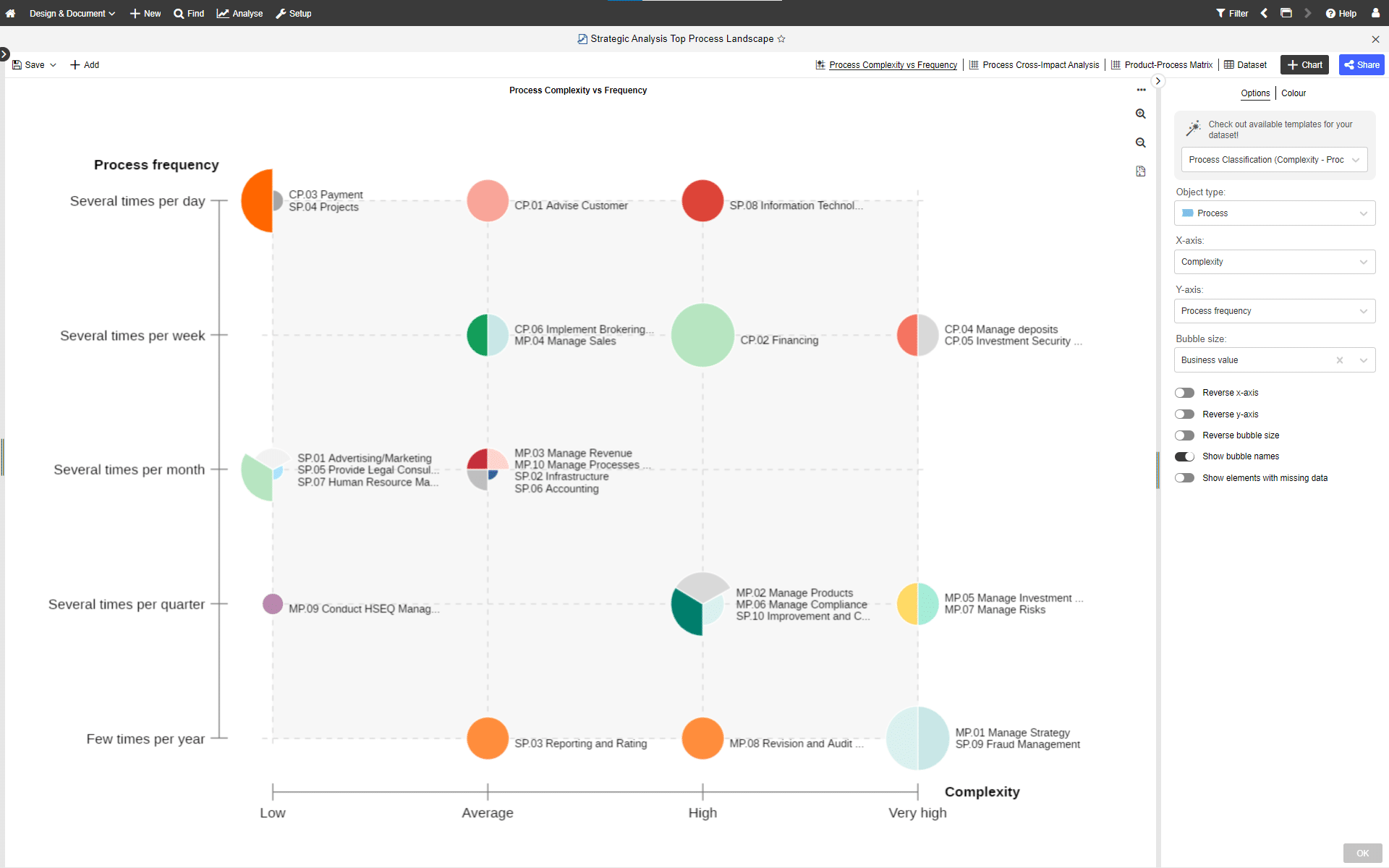

Begin by taking a comprehensive view of your organizational processes. Using a BPM tool like ADONIS can greatly aid in this endeavor by helping document, analyse, and optimize processes effectively. This involves understanding the broader process portfolio and aligning it with the organization’s needs. Once you have a clear overview, pinpoint the specific task or process you intend to standardize. Consider its significance in the larger organizational context, emphasizing why standardization is crucial for operational efficiency and desired outcomes.

Use ADONIS to analyse your process portfolio and identify the processes to standardize

2. Define the Objective

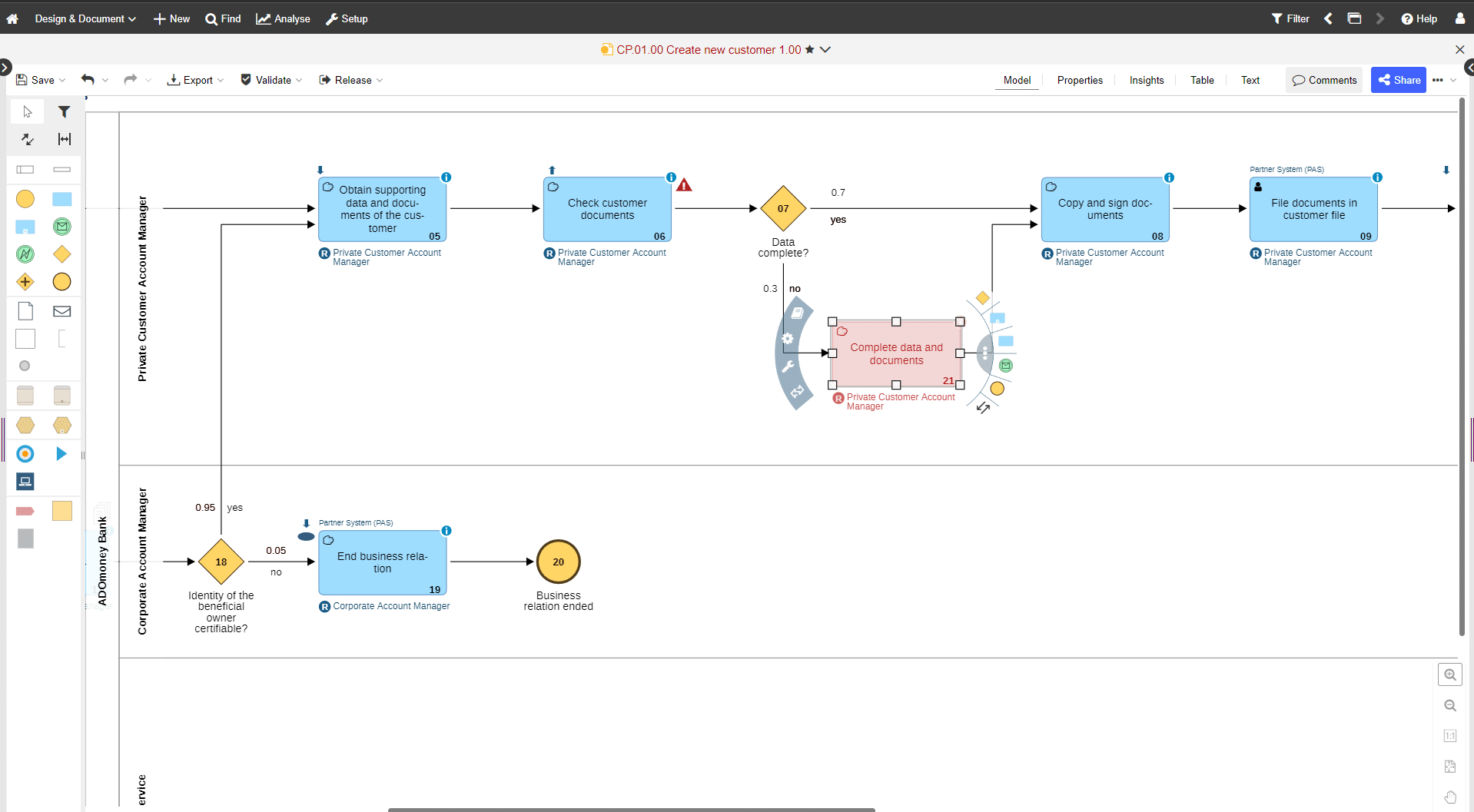

The first step is to explicitly outline the purpose of the SOP. It’s essential to thoroughly grasp the process in question. Breaking it down into manageable, distinct steps is pivotal. Consider adopting best practices such as using BPMN 2.0 modelling standard to model business processes. This approach provides a visual representation that elucidates each step and its implications, offering a clear and comprehensive view. By modelling the business process, you gain insight into the sequence and impact of each step, facilitating a more informed and structured approach to defining the SOP’s objective.

ADONIS fully supports BPMN 2.0 and is the best tool on the market for modelling and documenting business processes

3. Document Step-by-Step Instructions

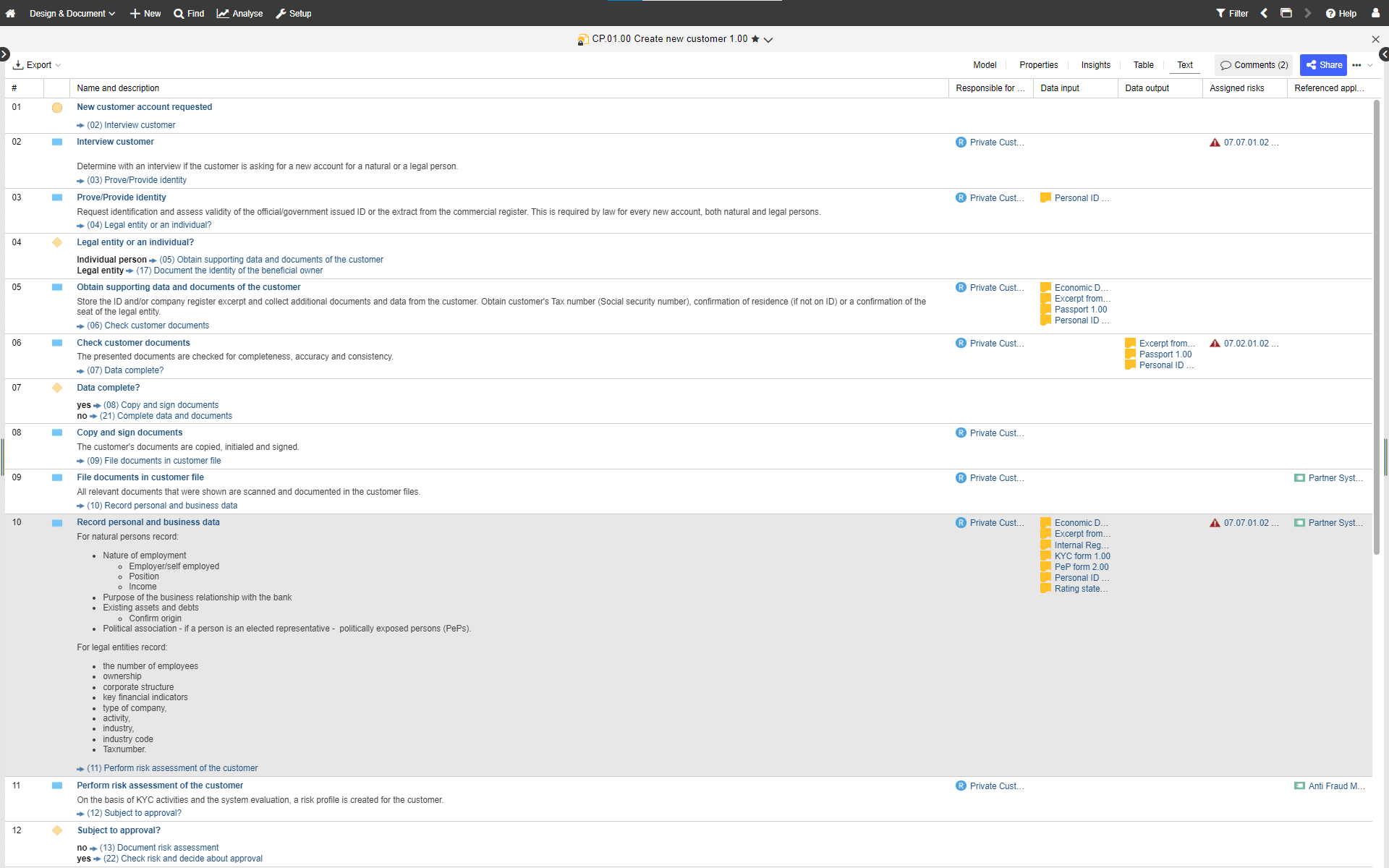

Once you’ve identified the process and its objectives, proceed to document clear and sequential instructions. Ensure that each step is broken down into easily understandable actions. Use straightforward language that anyone within the organization can follow. Detail who performs each step, what actions they need to take, and how they should execute these actions.

Use ADONIS to capture details of each text and write concise and precise instructions for each task execution

4. Include Visual Aids (if applicable)

Consider supplementing your written instructions with visual aids. Diagrams, flowcharts, or images can significantly enhance comprehension, especially for complex processes. Visual representations provide a clear overview and reinforce understanding by illustrating the flow and relationships between different steps.

5. Consider Safety and Quality Measures

Incorporate any necessary safety precautions or quality standards relevant to the process. Ensure that these measures are explicitly outlined within the SOP. Clear guidelines regarding safety and quality assurance are crucial to maintaining standards and mitigating risks.

6. Review and Validation

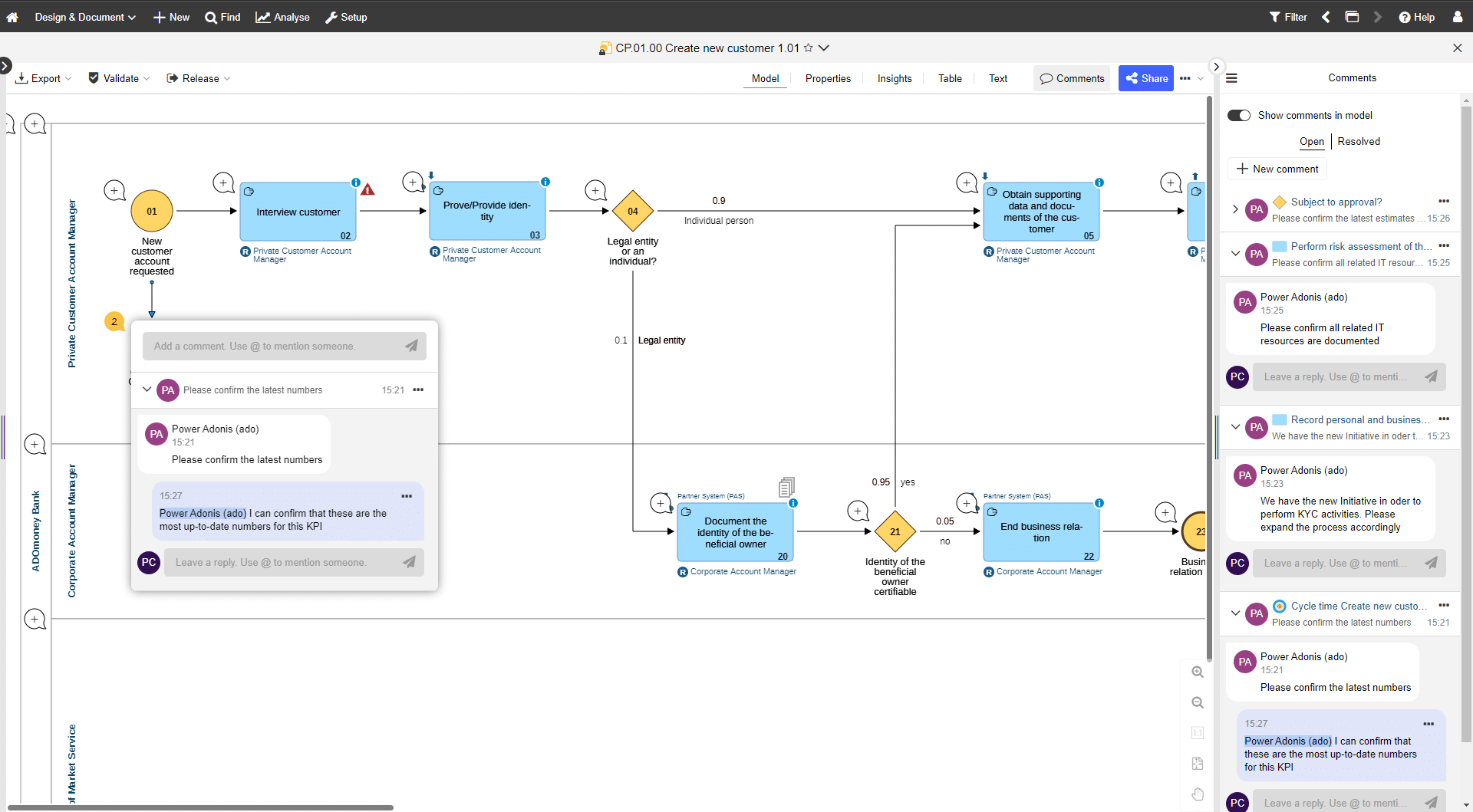

Engage relevant stakeholders or subject-matter experts to review the SOP. Seek their input to verify the accuracy, completeness, and practicality of the documented procedures. Collaborative validation ensures that the SOP reflects the best practices and expertise within the organization. With tools like ADONIS, it has never been easier to get all stakeholders to the same page.

Collaborate live with your colleagues and other stakeholders within ADONIS

Hint: Visit our blog to find out how to promote BPM in your organization and achieve greater engagement in your process management initiatives..

7. Implement and Train

Once validated, implement the SOP within the organization. Conduct training sessions to ensure all individuals involved understand and can proficiently execute the procedures outlined in the SOP. Effective training is essential for successful SOP implementation.

8. Regular Review and Updates

Establish a system for regular reviews and updates of the SOP. As processes evolve or new insights emerge, ensure that the SOP remains up-to-date. Periodic revisions maintain the relevance and effectiveness of the procedures outlined.

9. Document Control

Implement a structured document control system for the SOP. Maintain version control to track revisions and ensure accessibility to the latest SOP by all relevant personnel.

10. Measure Effectiveness

Continuously monitor the effectiveness of the SOP in practice. Gather feedback and data to assess if the SOP is achieving its intended objectives. Regular evaluation allows for refinement and optimization of the SOP over time.

Summary

At the end of the day, creating good Standard Operating Procedures (SOPs) is all about making work easier and better. It starts with understanding what needs to be done, breaking it down into simple steps that anyone can follow. Safety and quality are key, and it’s important to make sure everyone knows what to do. By checking and improving regularly, SOPs stay useful and keep things running smoothly. SOPs aren’t just rules; they’re the way we turn big plans into everyday success, helping us do our best work every day.