Introduction

Process optimization is the driving force behind organizational efficiency, allowing businesses to fine-tune their operations for maximum output. One of the most effective methods in this journey is process simulation.

This approach mimics real-life scenarios, offering a platform to test process times, costs, and decisions based on recorded probabilities. Let’s delve into the dynamic world of process optimization and uncover the steps that lead to enhanced efficiency.

Process optimization meaning

Process optimization refers to adopting structured methods, strategies, and technologies to improve a specific process within the parameters of a project or initiative. It aims to make the process more efficient, logical, and inexpensive while ensuring that important constraints are not violated.

Why do we optimize processes?

Process optimization is important to streamline operations and maximize resource utilization in project management. It improves overall output, reduces waste, and minimizes errors. Optimizing processes is vital when managing multiple processes, leading to efficient and effective decision-making.

In times of fierce competition and continuous disruption, every business manager, process owner, department head, or team lead needs to stay on top of their operational processes, constantly. Optimal effectiveness and efficiency of key processes is essential to your competitive position, and many times is what makes all the difference between surviving and thriving in the business arena.

Today, process automation is many times referred to as the ‘silver bullet’ for achieving operational excellence – be it through low-code/no-code automation, or ERP systems. But what we often forget, is that not every process is fit for automation and businesses need to analyse their processes first to determine the optimization potentials and the best-fitting means for automation. This is particularly important since automation tends to magnify the inefficiencies, when applied to inefficient processes (more on this in our blog post on process automation steps).

That’s why identifying the problem areas and opportunities for improvement are vital first steps in refining your processes and realizing their full potential.

There’s a saying that the first leg of any process optimization initiative lies directly in the process’ documentation itself. And that’s very true. By noting down the steps, decision points, process paths, responsibilities, handovers etc., the process analysts can already identify the obvious weaknesses in the process design.

Oftentimes, the pure process documentation can already reveal that there is no one, clear process in place – but rather many variants, with tons of exceptions. Writing these processes down, or modelling them in a BPM tool, can already help you harmonize these variants and create transparency for all parties involved. Alternatively, in the case of complex processes – and sufficient budget – process mining is another great approach for discovering how processes really run in your organization, thus delivering valuable input for subsequent analysis and optimization.

Well-documented processes typically easily unmask potentials for further optimization. And the goals of such optimization efforts may be:

- To minimize process execution time, cycle time, and/or cost

- To maximize throughput

- To reduce redundancies and inefficiencies

- To minimize manual intervention / non-standard processing (escalations)

- To maximize process quality (maximize the number of desirable outcomes; minimize process failures)

- To minimize process variants and further standardize the processes

- And alike

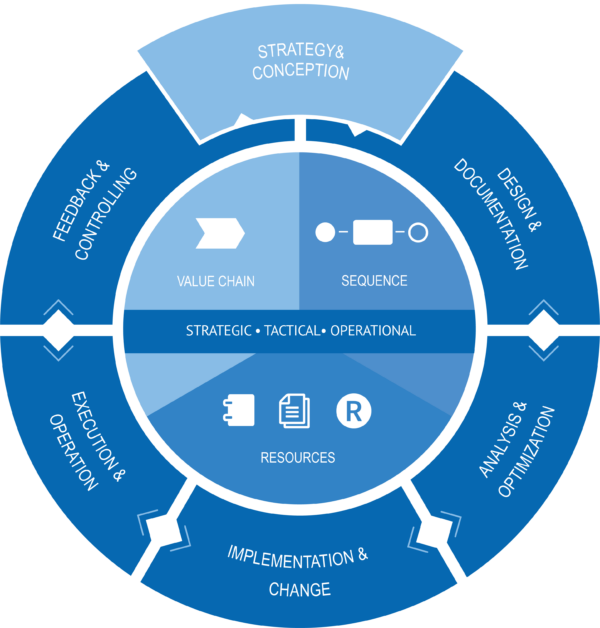

In order to realize one or many of these objectives, businesses are in need of a pragmatic, easy-to-execute procedure model for analyzing and optimizing of their business processes. Such procedure models can seamlessly be integrated into the existing management approaches, such as the PDCA (Plan-Do-Check-Act), or – for organizations with an established process management practice – the Process Management Life Cycle (PMLC).

Example of BOC Group’s Process Management Life Cycle

Scope of a Process Optimization Initiative

Most organizations already have an idea about which processes require optimization – be it due to a high number of complaints from customers, a noticeable inefficiency due to endless cycle times, or an observation of repeating loops and escalations. Moreover, many companies also have regularly running process assessments, or might be doing analyses based on their process landscapes.

However, on top of clearly defining and stating the scope of your optimization initiative, it’s equally as important to narrow it down, before you specify the concrete objectives for the measure at hand. Do you intend to optimize the generic production process, or rather the production process of a specific good? Are all your submission-to-bind processes in scope for optimization at your insurance company? Or rather only the vehicle insurance business segment? Such a detailed scope definition is paramount, in order to determine who needs to be involved and ultimately to define the actual optimization measures themselves.

Lastly, when optimizing processes make sure that your targets are clearly defined and understood by everybody involved. Shall the processes in scope be optimized for quality, time or cost? What is the concrete target, and how can potentially conflicting interests be managed?

Process Optimization Step By Step Guide

Process optimization is the backbone of organizational efficiency. By streamlining workflows and identifying areas for improvement, businesses can enhance productivity and achieve better results. In this guide, we’ll explore eight fundamental steps for effective process optimization in a professional yet straightforward manner.

1. Process Mapping

Begin by mapping out your current processes. This step involves visually representing each step, allowing you to identify bottlenecks, redundancies, and opportunities for improvement.

2. Data Collection and Analysis

Gather relevant data to assess the current state of your processes. Utilize key performance indicators (KPIs) to measure efficiency and identify areas that require attention.

3. Identify Pain Points

Pinpoint pain points within your processes. These are areas where delays, errors, or inefficiencies occur. Understanding these pain points is crucial for targeted optimization.

4. Set Clear Objectives

Define clear objectives for optimization. Whether it’s reducing turnaround time, minimizing errors, or improving resource allocation, having specific goals will guide your optimization efforts.

5. Implement Changes

Introduce changes based on your analysis and objectives. This may involve redesigning workflows, incorporating new technologies, or retraining staff. Ensure that changes align with your optimization goals.

6. Monitor and Measure

Continuously monitor the optimized processes. Use analytics to measure key metrics and assess whether the implemented changes are delivering the desired improvements.

7. Employee Involvement and Training

Engage employees in the optimization process. Provide training to ensure that the workforce is well-equipped to handle the modified processes efficiently.

8. Continuous Improvement Culture

Establish a culture of continuous improvement. Encourage feedback, regularly reassess processes, and stay abreast of industry best practices to ensure ongoing optimization.

By following these eight steps, organizations can systematically enhance their processes, fostering a culture of efficiency and continuous improvement.

Hint: Get a summary of these essential steps in our free Process Optimization cheatsheet.

Benefits of Process Optimization

In the dynamic landscape of business, achieving optimal efficiency is paramount for sustained success. Enter process optimization, a strategic approach that offers a multitude of benefits to organizations. Let’s explore the key advantages in a professional yet straightforward manner.

1. Improved Efficiency

Enhances the overall efficiency of business operations by streamlining processes, reducing redundancies, and optimizing resource utilization. This improvement results in a more streamlined and effective workflow.

2. Risk Mitigation

Identifies and mitigates potential risks in various business processes, ensuring smoother operations with minimized disruptions. This proactive risk management approach enhances the overall resilience of the organization.

3. Cost Reduction

Targets areas for cost-cutting without compromising quality, leading to financial savings through optimized resource allocation and streamlined workflows. This not only reduces expenses but also improves the overall cost-effectiveness of the business.

4. Better Results

Fosters a culture of continuous improvement and innovation, yielding superior outcomes by consistently refining and enhancing processes. This continuous enhancement ensures that the organization achieves better and more sustainable results.

5. Higher Efficiency

Maximizes output with the same or fewer resources, boosting productivity and enabling organizations to achieve more with optimized processes. This heightened efficiency ensures that the organization operates at its full potential.

6. Optimized Time

Ensures efficient use of time throughout various business processes, reducing time lags, accelerating project timelines, and enhancing overall time management. This optimization of time contributes to improved productivity and timely project delivery.

How to identify optimization potentials

Finding the best path to optimize processes

For some of the analysis steps (especially quantitative ones), the numerical data is crucial and should be sourced through interviews, surveys, log file analysis on used applications, or through process mining.

Nevertheless, many of the analyses can already be done based on the “static” process models, i.e. the designed or discovered flow charts. In the table below, you’ll find a summary of 9 such best practice methods:

| Technique | Goal | Measures | |

|---|---|---|---|

| 1 | Graphical analysis for the identification of excessive process loops (in quantity or “size”) | Understand the loops that are typically not value-adding and make the process more complex (as well as point towards any in-/deficiencies e.g. media breaks). | Streamline the processes by eliminating loops. Introduce and automate checks early in the process to ensure data quality and avoid loops later in the process flow.

If certain process paths are selected more often than they should be (e.g. loops due to insufficient quality in a QA / sign-off process), identify the steps in which the deliverable was created and determine whether better training, improved instructions, or a peer review could improve the quality, before passing it on to the final review / approval stage. |

| 2 | Process roles analysis | Analyse the number of different roles in a process, in particular identify handovers and (frequent) role changes, as these bear risks of delay, problems in data quality and processing. | Reduce the number of handovers to avoid waiting and transport times. Think of job enrichments that help you avoid handovers and change of task sequences.

If handovers or iterations are required in order to retrieve all essential input for continuing with the process, then better training, improved process documentation, or form-based workflow support may be good options for optimizing the preceding process steps. |

| 3 | Static process path analysis | Understand the process paths and identify the ones that may be unnecessary or seem “strange”. | Check if all process paths are truly needed, and eliminate special/rare cases accordingly. Foster higher process standardization. |

| 4 | Document input/output analysis | Analyse the process inputs/outputs and pinpoint any unnecessary documents/resources. Are all produced documents needed/used within this process or in any other process? | Define and align the process inputs and the necessary quality for such inputs. Question and eliminate the outputs that are not needed/used by another process. |

| 5 | Sequence flow analysis | Challenge the process flow and understand whether it is purely sequential. Determine the potentials for faster cycle/response times by introducing parallelities. | Parallelize tasks and activities where possible. |

| 6 | Value-add analysis | Find out your NVA (Non-Value adding) tasks vs. VA (Value Adding) tasks. | Identify tasks which could be eliminated, or “automated”, e.g. by using software robots, as part of RPA initiatives. |

| 7 | Automation potential analysis | Identify potentials for automation (RPA, workflow-based, etc.) by analysing your process’ current composition of tasks and IT support, as well as its predictability, complexity, frequency and business value. | Identify processes with automation potential and/or tasks, or groups of tasks which could be automated as part of RPA initiatives.

Prioritize and plan implementation projects together with your IT, based on the documented processes, their requirements and the analysis done. |

| 8 | Unhappy path & defect, waste analysis | Improve the happy end vs. unhappy end ration (defect ratio). | Focus on the tasks and decisions leading to defects and perform root-cause analysis for any process defects or waste. |

| 9 | Impact and dependency analysis | Run direct and indirect impact analyses (BIAs), to find out, for example, in which process a document is used. Or across multiple layers, for instance, in which applications a certain data entity is processed and which processes are using this application. | Enhance transparency on interfaces and responsibilities.

Streamline/standardize your processes, reduce the number of documents and perform data lineage. |

Many of these static analyses are manual and more qualitative in nature, whereas others rather emphasize the assessment of quantitative data. By enriching your process models with numerical information, you can complement your static analyses with dynamic assessment techniques, in order to examine additional information such as times, costs or process paths.

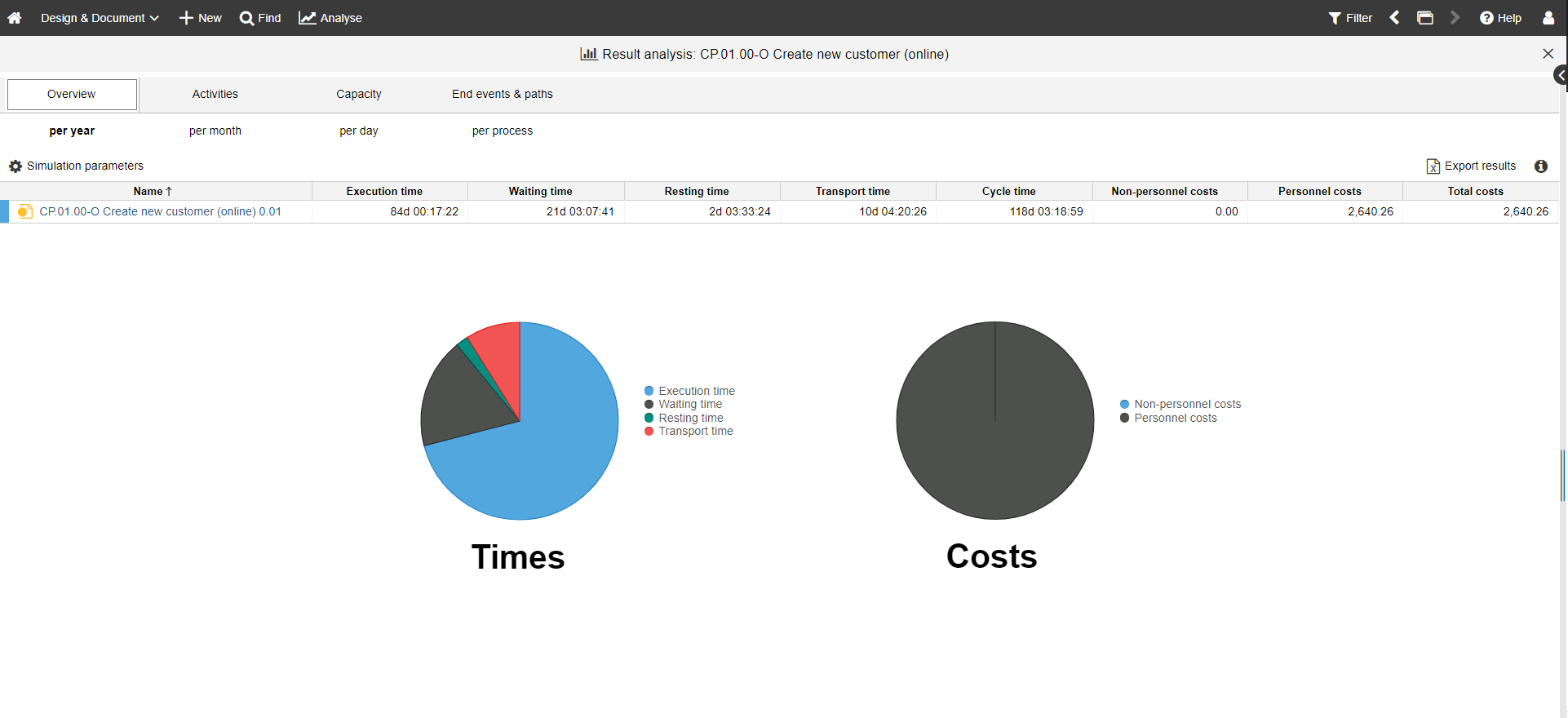

Process simulation

Process simulation is often the method of choice for this purpose – allowing you to mimic real-life scenarios and test your process times, costs and decisions based on recorded probabilities, as well as examine process results per path, or even for the entire process as a whole.

Example of process simulation results in ADONIS BPM tool

Such dynamic process analyses enable you to:

- Determine the number of process paths and their probabilities

- Identify your critical process paths, in terms of cycle times, processing times and frequency

- Find “costly” paths, and the paths that are in violation of the determined goals and service level agreements (SLAs), and improve / eliminate them

- Calculate the ratio between waiting times vs. cycle times, as well as the ratio between waiting times vs. execution time – the higher the ratio, the higher the optimization potential

- Detect “costly” tasks, find out why they take so long and how you could improve them e.g. through better IT support, automation/RPA, cheaper role executing the task, etc.

- Run personal capacity planning to determine the number of FTEs (full-time equivalents) and resources required

- Compare different process variants based of costs and cycle times, and prepare detailed cost/benefit and ROI calculations for sound decision-making

Incorporating quantitative analyses into your process evaluation can provide you with more tangible insights about your processes and how well, or efficiently they operate in reality – without disrupting the day-to-day business. Based on these assessments, you can adjust your processes in a targeted manner and thus give your process optimization a new boost.

Summary

The business competition bar is ever-rising and the importance of first-to-market, customer service, cost competitiveness, and quality are prevailing factors in determining an organization’s success, or undesirable downfall. Continuous business and process optimization are therefore no longer a choice, but a necessity for companies to stay ahead of the curve.

In this article, we’ve shared with you some our key insights and practices for streamlining of business processes, and discussed how analysis and optimization act as critical components in any automation initiative, or business transformation project as a whole. For a further deep-dive and exclusive look into some our lessons from experience, be sure to check out the process optimization webinar below.

And naturally, no business improvement initiative will fully prosper without a little help, whether it’s support from relevant stakeholders, or a smart tool that facilitates and empowers your optimization endeavors. With a BPM tool like our award-winning BPM suite ADONIS, you have an ideal companion to support you in all steps of your process’ lifecycle – from discovery and documentation, to optimization with graphical analyses, dynamic simulation, and beyond. Discover our BPM offering now and put your culture of continuous improvement in motion today!